AMPLIFIER CASE DEISGN AND PRODUCTION

Project Industry: Tech industry

Functional topic: Product design / Case design

Collaborators: Engineering team, Plastic Case injection team, Production team

Duration: 6 months

My role: Lead casing design and production efforts

00. Context

Contextualizing this project is a bit unique. The amplifier was a passion project of the CEO at the startup where I worked. He was the lead engineer on the product, and part of my role was to design and develop both the brand and the product’s casing.

01. Project objective

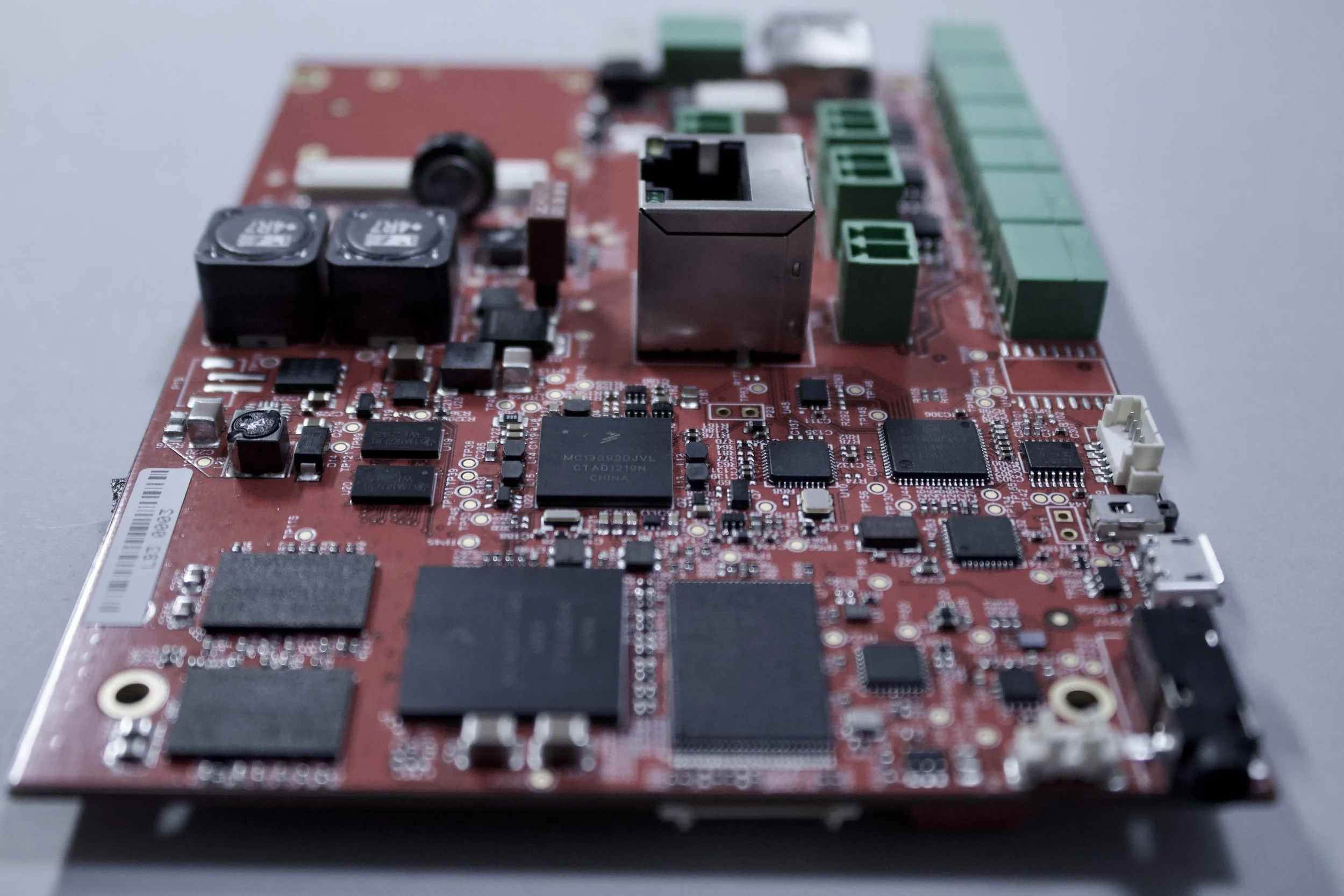

Design and develop an optimized casing for the amplifier that minimizes size, enhances aesthetics, and seamlessly integrates with the existing electronic components.

02. Approach

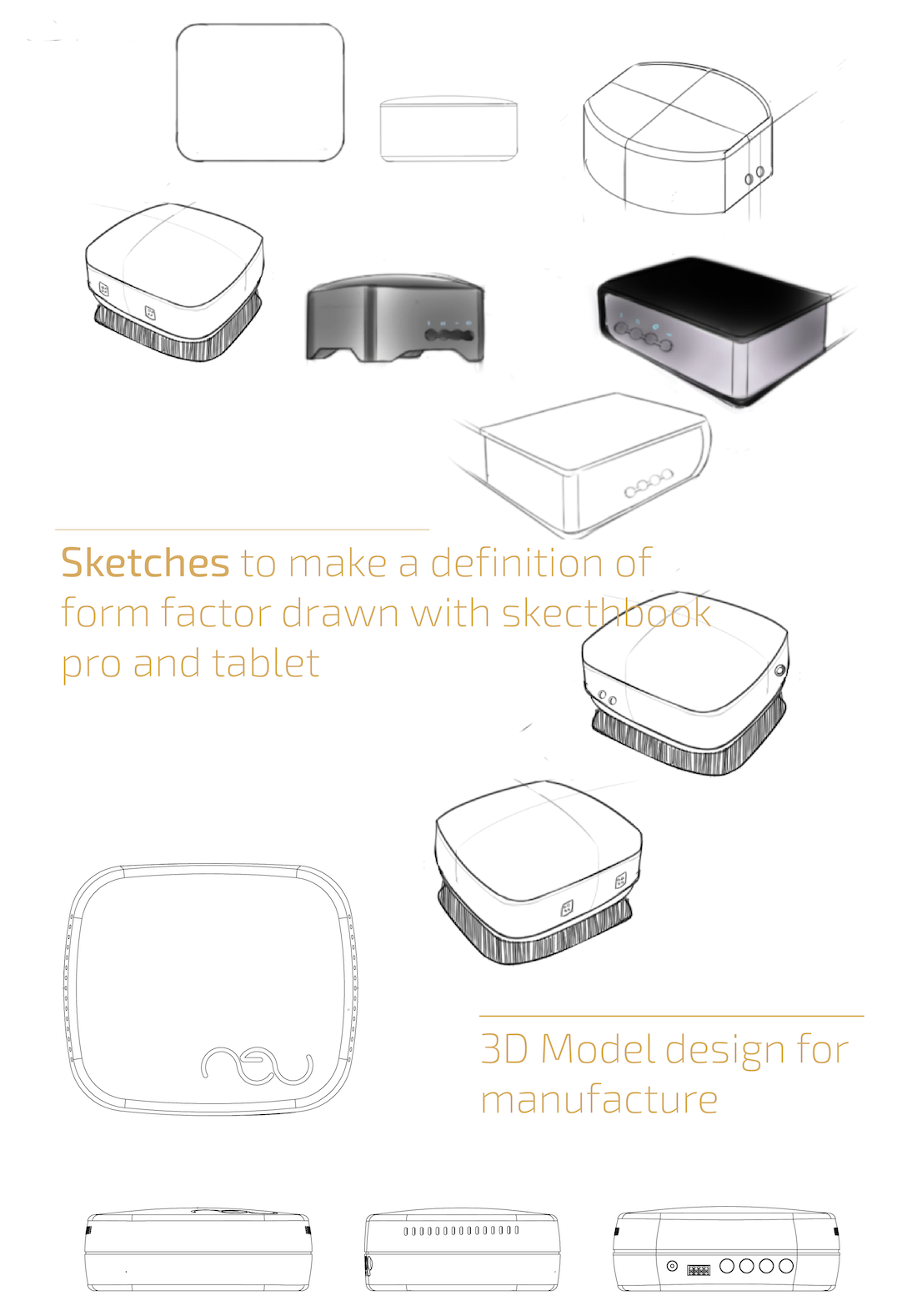

Used an iterative process of sketching and 3D modeling, refining the size and shape through multiple rounds. This allowed us to optimize the casing for both functionality and aesthetics, ensuring a perfect fit with the existing electronic components.

I then began researching materials and manufacturing processes for the build and assembly. This phase involved extensive 3D printing for assembly testing, while simultaneously working on the injection mold design which we outsourced to a partner

To deepen my understanding of the injection molding process, I completed a specialization, which allowed me to better understand the overall process and also build a network of experts from which I could outsource aspects of the process beyond my scope.

Once we finalized defining the assembly components and injection mold design, we began mold production and material testing for injection

03. Results

A production of 1000 Amplifier plastic cases

Brand, box, and instruction materials for the device